The mission: biodegradable plastics

Life as we live it would be impossible without plastics. But with their persistence, plastics are an enormous burden on the environment. Helmholtz researchers are working to resolve this conflict by searching for enzymes that break down plastic waste. A further goal is to bid farewell to oil by developing biodegradable plastics.

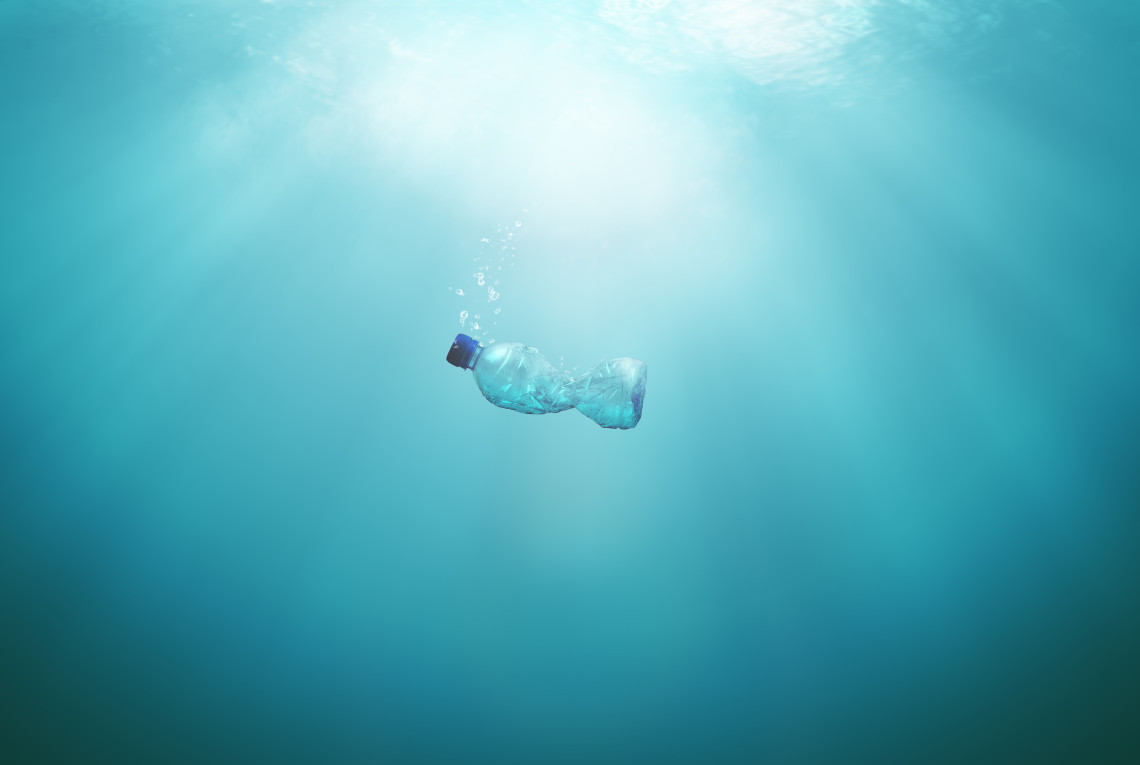

Clothing, toothbrushes, toys, cosmetics, food packaging: It is difficult to imagine our everyday life without plastics, but these synthetic materials pose an ecological problem. Unlike natural substances, they do not decompose. According to estimates by scientists, we produce over 400 million tons of them worldwide every year. Plastic waste in various sizes and mixtures is accumulating in nearly every ecological habitat, often with very harmful effects. Over long periods, evolution produces biocatalysts for almost all of Earth’s resources. They break down or process these resources, converting them into something else. Since plastics have only been mass-produced for a few decades, there are not enough such natural biocatalysts yet. This is where the PLASTISEA research project comes in. It is funded by Germany’s Federal Ministry of Education and Research and conducted by the GEOMAR Helmholtz Centre for Ocean Research Kiel.

“Compared with multicellular plants and animals, microorganisms usually have very short lifetimes and thus produce many generations in quick succession, so their genetic material can undergo rapid evolutionary changes,” says Erik Borchert, a marine ecology researcher at GEOMAR. “So we work with enzymes, which adapt quickly to changing environmental conditions, including new food sources.”

Enzymes are large biomolecules that consist mostly of proteins. They can be used to accelerate certain chemical reactions. The goal is to convert plastic into biomass. To that end, the researchers selectively extract enzymes from certain bacteria, which first have to be isolated. Every plastic is complex, and there are many different kinds, so a large number of different enzymes are needed to metabolize the existing plastic waste.

“We can only cultivate about two percent of the bacteria that are sources of enzymes for us,” Borchert says. “Metagenomics is helping us gradually gain access to the other 98 percent.” With metagenomic methods, genetic material can be extracted directly from environmental samples and analyzed. The team uses the entire amount of DNA from a bacteria sample, enabling the researchers to develop new and improved enzymes and other microorganisms that can break down synthetic polymers. “That already works very well on polyethylene terephthalate, or PET, which we know from PET plastic bottles,” Borchert says.

In the marine environment, ultraviolet radiation and friction play a major role in weathering the material by making the plastic surfaces porous and brittle, thus promoting the formation of micro- and nanoplastic particles. The enzymes can attach themselves to the small particles and break them down more easily. “Without such weathering, the enzymatic breakdown of polymers has been nearly impossible in both natural and industrial settings so far,” Borchert says. “But we’re working on other promising possibilities.” For example, marine sponges are a rich source of new bacteria that can break down plastics.

The aim is not to release such enzymes into nature, for example in the ocean, to dispose of plastic waste. It is completely unclear whether and how that could work. But above all, the consequences, including the unintended ones, would be unpredictable. “We’re working on applications that can be used in households and industry,” says Ute Hentschel Humeida, who heads the PLASTISEA project and the Marine Symbioses Research Unit at GEOMAR. “For example, these enzymes can be applied to surfaces that then act like filters.”

Sewage treatment plants equipped with such filters would be able to capture plastic nanoparticles and convert them to biomass, preventing them from ever reaching the environment. Cartridges on shower and washbasin drains could do something similar. Cosmetics, shower gel and other products contain nanoplastics that could then be kept from reaching sewage treatment plants in the first place. “This is already technically possible for certain kinds of plastics,” Borchert says. “Exhaust and particulate filters have made industrial plants and cars more environmentally friendly, and the same thing can be done with plastics in many applications.”

Converting petroleum-based plastics to biomass is an important step toward a sustainable economy, but the path to a circular economy goes further. If we abstain from using petroleum-based materials in the future and replace them with bio-based ones, that will have two advantages. First, fossil resources such as oil are limited. Sooner or later, they will have to be replaced by alternatives in any case. Second, bio-based and thus biodegradable materials have a much lower impact on ecological stability than plastics. Enzymes are also one of the things such materials are based on. “In the lab, we can reprogram microbes to convert a renewable substrate into a value-added chemical using enzymes,” says Nick Wierckx, who heads the Microbial Catalysis department at the Institute of Bio- and Geosciences in Jülich. Wierckx and his team are developing microbial catalysts for the bio-based production of chemicals and investigating the underlying cellular processes.

“Our preferred microbial workhorses are the Pseudomonas genus of bacteria,” Wierckx says. “They can metabolize a lot of different chemicals.” And that means they can be used to create many different products. Plastics and their properties are as varied as their applications. Some, such as food packaging, are only used for a short time. Others, such as those used in car bumpers, have to be long-lasting and especially rugged.

The substances used to produce bio-based plastics are correspondingly different. In addition to bacteria, Wierckx also works with fungi. “Aromatic compounds are toxic to most fungi, but some are perfect for producing organic acids,” he says. These acids serve as bio-based building blocks for new plastics. Among other things, his team modifies cell morphology to create organic acids more efficiently. “Our objective is to convert regional industrial waste streams to organic acids,” Wierckx says. This waste could then replace the pure sugar that has thus far been used as a substrate. This would enable new value chains – a new circular economy: Plastic could be produced from waste and would be biodegradable at the end of its life cycle.

The UpRePP and Glaukos projects that Wierckx is working on with his team do just that for bio-based textile fibers and coatings. “Our goal is to considerably reduce the carbon and plastic footprint of clothing and fishing nets, which have to be especially durable,” he says.